Coloured concrete is an extremely hard-wearing building material, however, the life of the decorative surface is greatly improved by sealing it.

This is because driveways, paths and many outdoor surfaces are constantly exposed to the accumulation of dust, grime and chemicals that are dropped, blown or washed onto the surface. Without an effective sealer coat, these pollutants seep in through the minute concrete pores, tarnishing and staining the colour. Sealing the surface creates a barrier that minimises the ingress of those materials.

Adding two coats of sealer improves abrasion resistance while creating a barrier between the concrete colour and the effects of dirt, sun, rain and chemicals.

By choosing to seal your decorative concrete with a CCS sealer or coating, you will:

- Dramatically improve the appearance of concrete by adding lustre and richness

- Protect decorative concrete from the harsh Australian weather

- Resist the marking effects of dirt, grime, salt, moss and oils

- Make concrete much easier to wash and clean

- Seal the pores in the concrete to restrict the flow of lime to the surface

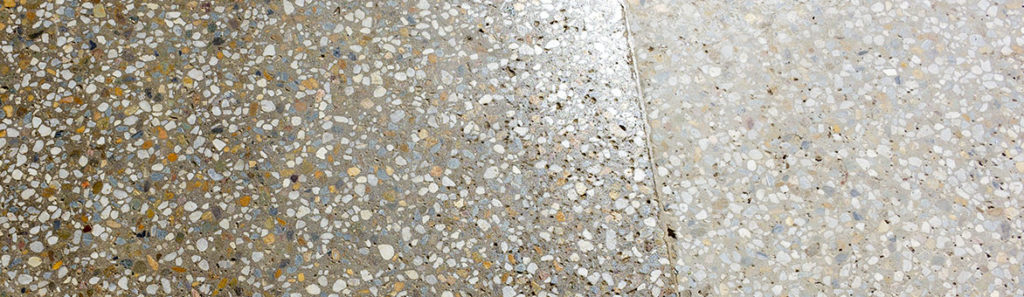

The photo below demonstrates the difference between a sealed (left-hand side) and unsealed section (right-hand side) of the same concrete surface after several years of weathering. The sealed section of the concrete remains brighter and cleaner after many years, whereas the unsealed section (with the pen) is dirty due to the accumulation of grime and dirt.

View Colour Master Sealer here.

It’s never too late to seal or reseal your concrete surface

With proper preparation, old concrete can be given a dramatic facelift with your choice of CCS Sealer. Adding colour to your existing surface is also possible with CCS Colour Master Sealer (mixed together with your desired CCS Sealer Tint).

For further information on where to purchase CCS Colour Master Sealer or if you are looking for an experienced applicator to apply the product (in Qld only) simply call us on 07 3412 8111 or 1800 077 744.

Unsealed Concrete

Preparation usually includes a pressure clean, degreasing to remove oil stains, and a light acid etch and wash with CCS HD Degreaser and CCS Citric Cleaner. Once these steps are completed and the concrete is dry, sealing can commence.

If you have mould or growth on your concrete, please contact the CCS Helpline to discuss the best method of removal on your concrete substrate.

Previously Sealed Concrete

Care and patience are required when recoating previously sealed concrete surfaces. The critical ingredient to a satisfactory job is to ensure that the new coat of sealer bonds to the existing sealer coat as well as the concrete surface. To successfully achieve sufficient bonding, recoating of sealed concrete (sealed with acrylic) should occur within 2-3 years of initial coating.

As the initial coating ages, it may react with the concrete below to form a very hard, yet somewhat brittle layer of sealer. The hard sealer layer can be difficult to dissolve when the new sealer is applied, causing whitening problems at a later date. To avoid such problems, we recommend applying the sealer in full sunlight (for exterior surfaces) to a small area – approximately two square metres, and evaluating the surface after six weeks, to determine if the sealers are bonding satisfactorily.

If whitening occurs on the sample area, consult our technical staff by phoning 1800 077 744 as it may be necessary to use a concrete stripper to treat the existing coating. If you suspect your concrete surface may be problematic or if you are uncertain about the preparation required before applying the sealer, we strongly recommend that you consider having the coating applied by a professional applicator.