A decorative concrete specification should include the basic information such as the selected colour and brand, the surface texture and the required slip resistance rating, the coating to be applied and sampling requirements.

Some basic CCS Specification templates are noted for specifier use.

For more specific specifications where multiple systems are used in conjunction; honed or polished concrete; precast or vertical off form concrete or specialist finishes, please contact the CCS Helpline on phone 1800 077 744 or fill in the form below.

As a specifier we understand that you are inspired by your local environment, from print media and the internet. If you have a specific look, image or reference point that you wish to achieve, please forward us your reference and we will be in contact with you to discuss how you can achieve this with CCS Colouring and Sealing solutions.

New Concrete Specifications

Grey concrete is to be integrally coloured with Concrete Colour Systems CCS (insert colour name) at the dose rate of (insert colour dose rate)____% per weight of cementitious content. Create surface texture using a broom finish (or nominate alternative) to meet a slip resistance rating of (insert rating P0-P5) as per HB198/AS4586.

Cure with Australian Standards compliant CCS Slab Clad R curing compound or used hessian kept consistently moist for 5 days.

As the completion of the curing period, remove dirt and remnants of the curing compound with CCS Degreaser. Rinse thoroughly and allow to dry.

Coat with Concrete Colour Systems CCS (insert CCS sealer type) penetrating OR CCS (insert sealer type) film-forming sealer. All CCS sealers should be prepared and placed in accordance with the Technical Data Sheet (TDS), available from the Technical Data Sheet page or the Helpline phone 1800 077 744.

Coat with CCS (insert CCS sealer type) penetrating OR CCS (insert sealer type) film forming sealer. All CCS sealers should be prepared and placed in accordance with the Technical Data Sheet (TDS), available from Technical Data Sheet page or the Helpline phone 1800 077 744.

On existing structurally sound concrete or newly placed concrete that is at least 28 days in age

Prior to proceeding with application of the CCS Stylepave Overlay system, prepare a site sample of 1m x 1m in a discrete area on site or alternatively on FC demonstrating colour, texture, patterning if any and sealer. Sample should be created by the contractor placing the CCS Stylepave Overlay System to demonstrate both the product use and the applicator finishing. Ensure the sample completely dry prior to inspecting and signing off an accepted reference.

To the area to be covered with CCS Stylepave Resurfacing System:

Dirty or soiled concrete is to be lightly ground and pressure washed with clean, freshwater. The surface is to be treated with Concrete Colour Systems CCS HD Degreaser to remove oil or grease. All major cracks need to be repaired with a suitable crack filler such as the Concrete Colour Systems CCS Epoxy Repair Kit. Minor cracks, that is a house key can not penetrate the crack do not require filling with epoxy. Any curing compound should be removed prior to application of this system.

For clean concrete surfaces that do not require building up or additional levelling, the surface should be primed with a diluted coat of Concrete Colour Systems CCS Super Polymer 2000 at the rate of one part Super Polymer to 3–4 parts water.

For clean concrete surfaces that require building up or additional levelling, the surface should be treated with one part Concrete Colour Systems CCS/ACS Neolastic mixed with 2 parts water. While the surface is wet with this solution, broadcast GP cement to the surface to create a slurry. Apply Concrete Colour Systems CCS/ACS Screed to the wet slurry to build up to the desired level. Allow to dry for a minimum of 24 hours.

Base Coat (this will provide grout colour): Mix one satchel of Concrete Colour Systems (nominate natural or colour eg. CCS Charcoal) Pigment Concentrate to one 20kg bag of Concrete Colour Systems Resurfacing Base and Concrete Colour Systems Super Polymer 2000 at the ratio of 2 litres of polymer to one 20kg bag plus up to 2-3 litres of water and applied to surface with a squeegee or hopper gun.

Application rate to busy shopping footpaths and malls with heavy pedestrian traffic is 4kg/m².

Where a pattern is required, apply either a pre-cut stencil or create design by adhering fibre/filament tape to dry base coat. If using filament tape, please specify the tape thickness – either 6, 9 or 12mm.

Top Coat: Mix one satchel of Concrete Colour Systems (nominate natural or colour eg. CCS Terracotta) Pigment Concentrate to one 20kg bag of Concrete Colour Systems Resurfacing Base and Concrete Colour Systems Super Polymer 2000 at the ratio of 2 litres of polymer to one 20kg bag plus up to 2-3 litres of water and applied to surface with a squeegee or hopper gun.

Application rate to busy shopping footpaths and malls with heavy pedestrian traffic is 4kg/m².

The surface texture should be a sprayed “light grainy” OR “ light broom” texture to meet a pendulum slip resistance rating of ________ (insert relevant rating from the Standards Australia Handbook HB 198/AS4686).

For a “Speckled” or “flecked”/contrasting colour – if required

Apply an addition Top Coat of Concrete Colour Systems (nominate colour eg. CCS Black) over placed topcoat in an ad hoc manner to achieve 15% coverage to create a multi-coloured effect.

Alternatively, specify a different texture for the Top Coat only (reference the rear cover of the CCS Stylepave Overlay textured colour chart for options).

When the surface is cool and dry, apply two coats of the CCS Armourthane OR CCS Decrathane as per manufacturers datasheet. Note the first coating of sealer should be applied as soon as the final coat is dry in order to lock in the polymer. Avoid wetting any of the products until the sealer is fully cured. Please note that the CCS Armourthane is solvent-based and will emit an odour.

Following application of the CCS Stylepave Overlay System, all existing control joints should be re-cut. Additional control joints can be placed if insufficient control joints are present.

The surface should not be opened to pedestrian traffic for a minimum of 48 hours. If possible, limit access for 7 days. Do not move vehicles, furniture or rubbish bins on the surface until fully cured at 7 days. Do not clean with high-pressure water or chemicals until the CCS Stylepave Overlay system is at least 7 days old.

Products should be applied according to the manufacturer’s application guidelines and data sheets in appropriate weather conditions.

Application on existing concrete using CCS Resurfacing Overlay

Ensure concrete is structurally sound, any cracks have been repaired and that all coatings, adhesives and friable matter have been removed from the surface.

Prime surface with a dilution of Concrete Colour Systems CCS Super Polymer and water as noted on the CCS Super Polymer technical data sheet and label.

Mix one satchel of Concrete Colour Systems (nominate base or colour eg. CCS Terracotta) Pigment Concentrate to one 20kg bag of Concrete Colour Systems Resurfacing Base and Concrete Colour Systems Super Polymer 2000 at the ratio of 2 litres of polymer to one 20kg bag plus up to 2-3 litres of water and applied to surface with a squeegee or hopper gun.

Immediately trowel with a 3-5mm notched trowel to create a consistent finish with no cold joints. Trowel finish to desired smoothness. Random stone texture is common for use with the Concrete Colour Systems CCS Rembrandt Stain System.

After the Resurfacing Overlay has cured for 24 hours, apply up to two coats of Concrete Colour Systems (nominate stain colour eg. Aztec Red or refer to Rembrandt brochure for a list of diluted colours) Rembrandt Stain at a rate of 1 litre per 8 square metres or as required to duplicate previously approved on-site samples. Apply with a brush, squeegee sponge or spray gun.

Second or third colours (if desired): After four hours another secondary colour can be applied. Apply one coat of Concrete Colour Systems (nominate stain colour or refer to Rembrandt brochure for a list of diluted colours) at a rate of 1 litre per 8 square metres.

(Optional) Saw cut or scribe designs into the surface as per attached drawing. This may be completed in either the wet CCS Resurfacing Base overlay or after the dried application of the second or third colour, depending on patterning required.

When the surface is clean and dry, seal with two coats of Concrete Colour Systems CCS Decrathane. Apply the first coat as CCS Decrathane Gloss, allow to dry, then apply the combined Concrete Colour Systems CCS Flatting Agent and CCS Decrathane Gloss to achieve a satin finish.

To increase the surface texture, apply Concrete Colour Systems CCS Glass Bead to the first coat of CCS Decrathane, allow to dry, remove excess with air blower then apply a second coat of sealer.

Products should be applied according to the manufacturer’s application guidelines and data sheets in appropriate weather conditions.

Surface colour and patterning to new, wet concrete

Pattern: Concrete Colour Systems stencil (nominate stencil design eg. Tile 270mm) and Concrete Colour Systems stencil (nominate border design eg. Soldier Course Brick) as manufactured by Concrete Colour Systems are to be used to create a pattern as noted in the project documentation.

Colour: Concrete is to be coloured with Concrete Colour Systems (nominate colour eg. CCS Black) Colour Hardener by applying it to the surface at a rate of no less than one 20 kg bag per square metre (refer to application rate recommendation table below).

Antique/Multi Colour technique (if desired):

Following on from the application of the CCS Colour Hardener and while the concrete is still in its manual form, Concrete Colour Systems (nominate Release Agent colour eg. CCS Rustic Brown). Release Agent shall be applied to all concrete surfaces. After application, make one or two passes with the CCS Stone Textured roller to embed the release agent.

After two days, remove any excess release agent by washing the surface with a light broom and water. Once completely dry, the concrete shall be sealed with two coats of a Concrete Colour Systems film-forming sealer such as CCS Hardseal Advanced, CCS Hi-Build Enduro or CCS Armourthane.

Products should be applied according to manufacturer’s application guidelines and data sheets in appropriate weather conditions.

Rate of application of the CCS Colour Hardener depends on the service conditions which the floor will be exposed to.

Recommended rates are as follows:

Domestic driveway, paths and car parks with vehicular traffic under 3 tonnes

2-2.8kg of CCS Colour Hardener per square metre (7-10m² per 20kg bag)

Public roadways and industrial hard stands

3.3kg of CCS Colour Hardener per square metre (6m² per 20kg bag)

Busy shopping footpaths and malls with heavy pedestrian traffic

4kg of CCS Colour Hardener per square metre (5m² per 20kg bag)

Option 1 – Utilising CCS Colour Hardener to create a base colour

The concrete shall be coloured with Concrete Colour Systems (nominate colour) CCS Colour Hardener at a rate of one 20kg bag per 7-10 m². Concrete Colour Systems (nominate colour) CCS Release Agent shall

be applied to all concrete surfaces to be imprinted with (nominate design) Textured Mat.

After 2 days, wash off any excess CCS Release Agent. Once completely dry, the slab should be sealed with 2 coats of CCS Hardseal Advanced, CCS Hi-Build Enduro or CCS Armouthane sealer. Traction aids can be added to the sealer to improve texture.

Option 2 – Utilising CCS Pigment Concentrates full depth colour to create the base colour

Concrete is to be integrally coloured with Concrete Colour Systems nominate colour eg. CCS Onyx 44) Pigment Concentrate. One pre-formulated bag is to be added per one cubic metre of (nominate strength) MPa concrete containing(i.e. ‘grey’ or ‘off white’ ) cement. Concrete Colour Systems (nominate colour)CCS Release Agent shall be applied to all concrete surfaces to be imprinted with (nominate design) textured mat.

After 2 days, wash off any excess CCS Release Agent. Once completely dry, the slab should be sealed

with 2 coats of CCS Hardseal Advanced, CCS Hi-Build Enduro sealer or CCS Armourthane. Traction aids can be added to the sealer to improve texture.

Note that if CCS Clear Liquid Release Agent is applied, the wash-off process may not be required.

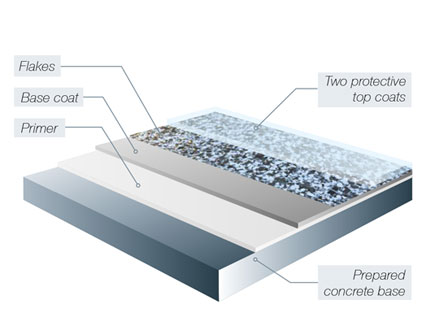

CCS Galaxy Epoxy Flooring offers a single uniform finish OR multi colour with EITHER a decorative flake or decorative flake/sand combination or antique pearl finish with CCS Metallic Pigments. Please specify the desired finish.

Surface Preparation

All surfaces to be treated should be structurally sound and all previous coatings, adhesives, efflorescence or laitance should be removed by mechanical grinding or abrasive blast cleaning, high pressure water blasting, mechanical scrubbing or other suitable means. Grinding is highly recommended on both old and new concrete surfaces to ensure correct bond of products.

Holes, non-structural cracks and other surface deformities should be repaired using CCS Epoxy Repair Kit in accordance with the technical data sheet. New concrete floors should be at least 28 days old.

Application Specification for a single uniform colour

1st Coat – CCS Ultra Epoxy Primer/Sealer which can be tinted if required using CCS Universal Tint.

2nd Coat – CCS Duratrac HB Epoxy which can be tinted using CCS Ultra Epoxy Tints. Or CCS Ultra Epoxy WB which is pre-tinted N35 Grey.

3rd Coat – CCS Armourthane or CS FlakeKote 100S.

4th Coat – CCS Armourthane or CCS FlakeKote 100S.

If a traction aid is required, then apply CCS Slip Reduction Granules between 2nd and 3rd coats by broadcasting evenly onto the wet coat. Allow to dry. Remove excess with air blower.

Follow directions on Technical Data Sheets for all products.

Application Specification for a multi colour with CCS Decorative Flake or CCS Stone Grip

1st Coat – CCS Ultra Epoxy Primer/Sealer which can be tinted if required using CCS Universal Tint.

2nd Coat – CCS Duratrac HB Epoxy which can be tinted using CCS Ultra Epoxy Tints. Or CCS Ultra Epoxy WB which is pre-tinted N35 Grey. Apply CCS Decorative Flakes by broadcasting evenly onto the wet coat. Allow to dry. Remove excess with broom and air blower and scrape if a relatively smooth surface is required.

3rd Coat – CCS Armourthane or CCS FlakeKote 100S.

4th Coat – CCS Armourthane or CCS FlakeKote 100S.

Follow directions on Technical Data Sheets for all products.

Application Specification for a multi colour with CCS Metallic Pigments

1st Coat – CCS Ultra Epoxy Primer/Sealer which can be tinted if required using CCS Universal Tint.

2nd Coat – CCS Duratrac HB Epoxy which can be tinted using CCS Ultra Epoxy Tints. Or CCS Ultra Epoxy WB which is pre-tinted N35 Grey. Mix appropriate amount and different colours of CCS Metallic Pigments into the epoxy. Apply using a square edge trowel in a swirl/figure of eight motion or as required pattern using various techniques.

3rd Coat – CCS Armourthane or CCS FlakeKote 100S.

4th Coat – CCS Armourthane or CCS FlakeKote 100S.

Follow directions on Technical Data Sheets for all products.

Request a Specification

Complete the form below and we will provide you with the appropriate CCS product/s specification guidelines.