What is slip resistance and how can you improve the slip resistance of concrete?

No matter the project, having a high slip resistant floor assists in reducing the risk of accidental falls. In addition to the floor, several other factors can contribute ranging from lighting conditions, state of the floor, people’s footwear, and contaminants within the space among others. When considering concrete surfaces, the final finish, use, texture, sealer, and cleaning method and program need to be factored into discussions of slip resistance and the need for slip-resistant additives.

What is slip resistance and why it is important?

Slip resistance is measuring the capability of a surface to reduce the risk of accidental falls in both wet and dry conditions. It depends on the finish of a surface (smooth or textured) and various environmental conditions which influence the likelihood of a person to fall.

Slips, trips, and falls can occur in any environment, so it is important to prevent the possibility and risk of an injury. It is also essential for commercial, government, multi-residential, and industrial buildings to consider the compliance requirements relating to slip resistance.

Listed below are four main factors that contribute to an accidental slip, trip or fall.

- External factors

- These include the condition of the floor; are there risen cracks? Is the floor level, particularly at joints or cracks? Is there liquid on the floor? Does the liquid pool on the surface?

- Internal factors

- These factors in people’s responses (voluntary or involuntary) to their surrounding environment. Examples include stress-related responses, fatigue-related actions, symptoms of drug use.

- Pathologies

- Includes things like the age of a person, impaired vision and footwear worn in areas. This section also considers the likelihood of instantaneous health conditions like a stroke or if people with disabilities will be using the area.

- Environmental factors

- This addresses things like lighting conditions and contaminations on the floor, the slope of the floor, the use of the area, and cleaning methods used.

- It is important to note that environmental factors can be minimised through implementing better design practices and staff training for specific areas.

Variables to consider when specifying a concrete surface

Let’s move to the floor and discuss the varying elements of a concrete surface that need to be considered when specifying. Each of the below elements influences how slip-resistant a concrete surface is. These elements include:

- Finish

- Is the surface an interior or exterior surface? The options for interior and exterior surfaces differ based on the changing environmental conditions. Consider the final use of the area, the desired profile, and the final texture (see below point). For example, a rough surface finish will provide a better result and therefore be a better solution long-term; if a coating was added after, it is important to maintain the surface as the coating will erode over time.

- Texture

- What texture will work aesthetically and functionally – polished concrete, broomed texture, rock salt pattern or exposed aggregate? These are just a handful of textures available. Utilising a rougher texture like broom or coving trowel will provide a better slip resistant result while also being a long-term solution.

- Sealer

- Have you chosen a film-forming or penetrative sealer? Film-forming sealers can enhance the surface whilst penetrating sealers retain a natural finish. What maintenance is required? Penetrating and surface coating sealers have different benefits and depending on the final surface finish, a slip-resistant additive may be needed as well. If a sealer or topcoat is added at the end it is important to care and maintain the surface as it will erode over time and may reduce the level of slip resistance.

There is a range of additional considerations for the variables of a concrete surface that factors in texture, colours, and project use to name a few.

We have completed a variety of case studies with test results that demonstrate concrete can reach the desired slip resistance ratings. Please get in contact with us so we can share them with you.

Slip-resistant additives and solutions for existing concrete surfaces

If you desire a polished or decorative finish, consider the final application. Additionally, the concrete surface should be completed in a finish that meets the slip-resistant requirements for that application. Very smooth surfaces may not be suitable around wet areas such as pool surrounds. Some solutions include:

- Grinding the surface with low grit will show the aggregate and have some texture. This is commonly referred to as honed concrete and can be used in some external environments.

- Sand blasting a surface improves slip resistance with water, but not oil

- Strong acid etches improves slip resistance with water, but not oil. It is important to consider the surrounding environment when washing off the acid.

- Traction aids such as glass beads, crushed glass, carborundum or dried sand sandwiched between the two topcoats of film-forming sealer can also improve the texture. Consider that these traction aids are typically applied by hand and so may not be evenly spread. Any traction aid in this matter will evenly abrade so inspection and testing should be added to any maintenance program.

It is important to note that there is no one “correct” or “safe” level of slip resistance for surfaces as it depends on all the factors we have listed in this article. However, for commercial and industrial projects, they must meet Australian Standards. Completing the concrete in a finish that meets the requirements of slip resistance for the desired application is crucial. If you would like to understand what standards must be met, please get in contact with us.

How to test the slip resistance of concrete surfaces?

There are two ways to measure the level of slip resistance of concrete surfaces: a wet pendulum test and a ramp test. A NATA accredited contractor will be able to perform both styles of testing.

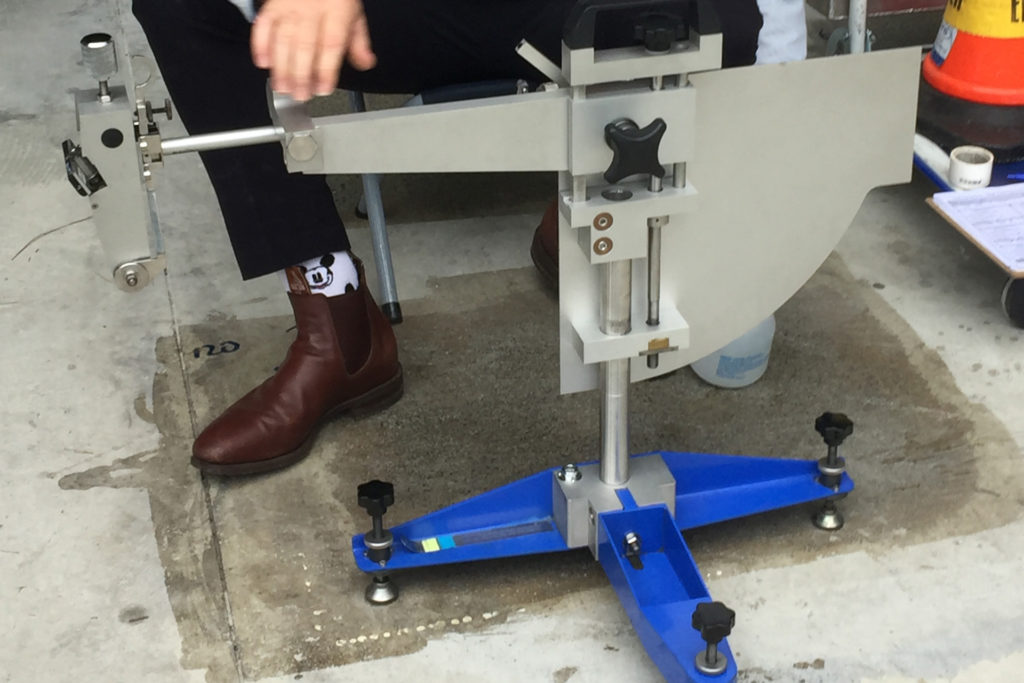

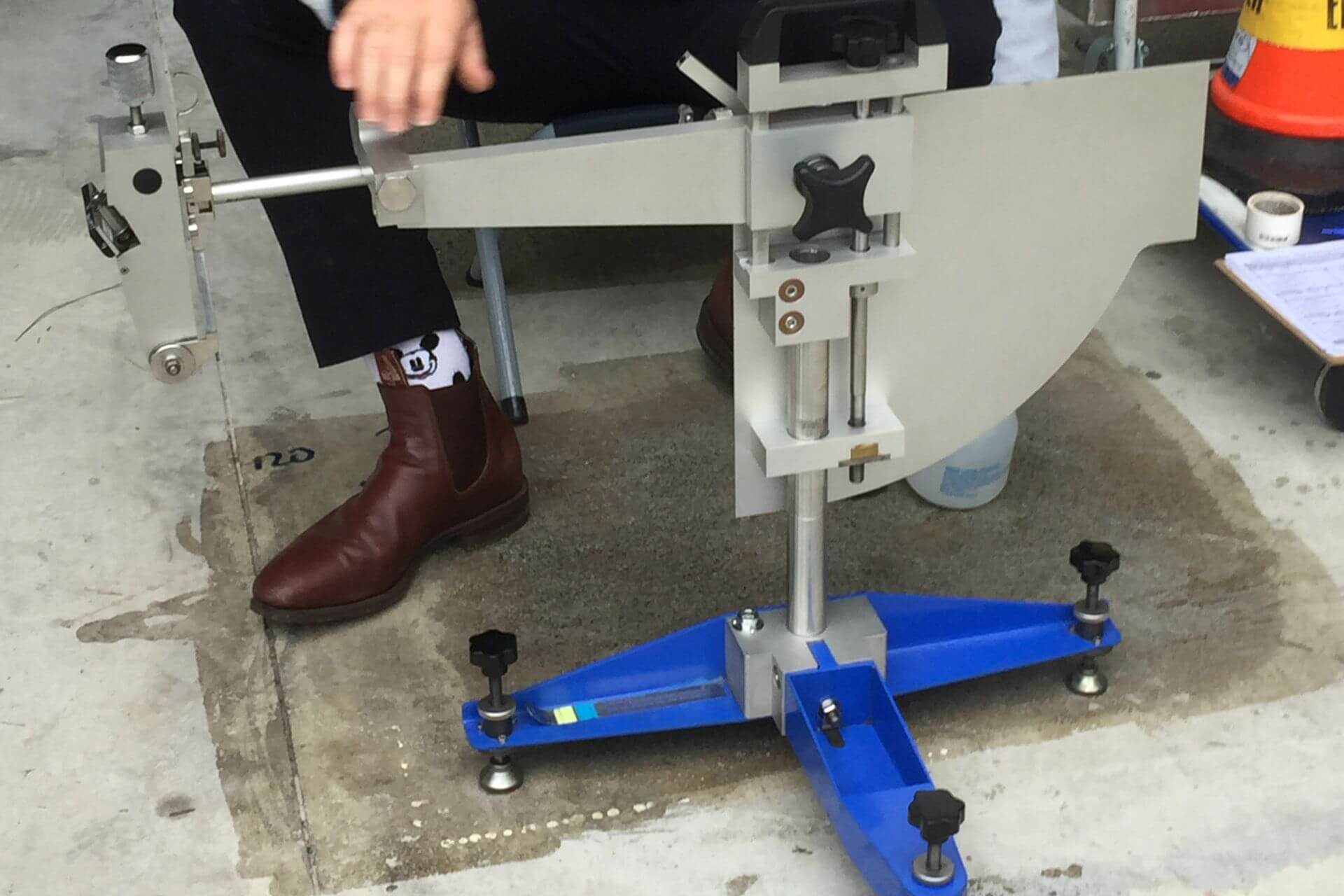

Wet pendulum test

A wet pendulum test is considered the most viable and cost-effective method to use as it is a portable instrument allowing a NATA accredited contractor to test the slip resistance of new or existing concrete surfaces on a project site. Being the only test capable of being used in situ on a project site, it is considered to be a highly accurate method of testing which can simulate both barefoot and shoe-wearing conditions on the surface. Another advantage of utilising the wet pendulum test is the ability to measure the slip resistance of contaminants other than water on the site, such as oil or soapy liquid, to understand their potential impact on the surface.

Let us tell you how it works:

- A rubber slider is attached to a spring-loaded foot at the end of a pendulum arm

- The pendulum arm is released, allowing it to swing so that the slider contacts the wet surface over a set distance of 126mm

- The extent to which the pendulum fails to reach its release height on the overswing is used as a measurement of the slip resistance

- The test is repeated multiple times to achieve an average score which is then checked against the Australian Standards.

- Multiple sections of the surface are tested to ensure consistency in the results

There is a minimum area of 1m² of the placed, textured, and sealed concrete that is required to conduct the wet pendulum test.

Ramp test

This test requires a portion of the concrete surface to be cut out and shipped to a laboratory for testing under controlled conditions by human subjects. Due to the nature of the test conditions the results can be a little subjective, however, there are often several NATA accredited contractors perform the test to reduce any bias. How does this test work?

- The test piece of concrete is attached to a ramp with liquid applied to its surface, typically water and oil.

- An operator walks forwards and backwards on the ramp while progressively increasing the ramps angle of inclination until they reach their “zone of insecurity”. This is where the operator either experiences slipping on the surface or senses they will fall is the angle is increased further.

The downside of this test is cutting a 1m² piece of concrete from the job and transporting that to a lab for testing. This isn’t an economical test and typically takes much longer than the Wet Pendulum test to complete.

Maintaining floors and their level of slip resistance

Proper maintenance of a floor surface ensures that the level of slip resistance is not reduced by contamination or wear from use. However, to ensure the surface retains its slip resistance a selection of appropriate cleaning procedures should be considered to maintain the floor.

There are multiple elements of the project and the application of concrete which need to be considered when evaluating the slip resistance of concrete surfaces. The final use of the area, along with a range of additional factors that are out of your control needs to be considered as well. Knowing how the concrete surface will be finished, textured, and sealed will assist and dictate whether slip-resistant additives are required to improve the slip resistance. Remember to consider concrete finishes that match the requirements of slip resistance for the desired application, particularly in commercial and industrial settings. It is good practice to employ a method of testing the slip-resistant nature of your concrete surface. Utilising a wet pendulum test is the most economical test which allows for testing on-site on the finished surface and is completed by a NATA accredited contractor. This test is also a highly accurate method of testing for both barefoot and shoe-wearing conditions. If you need assistance with the Australian Standards on slip resistance, please get in touch with us. Finally, the maintenance and cleaning procedures need to be considered to ensure the surface retains its slip resistance.

If you have any questions regarding the slip resistance of Concrete Colour Systems products, please contact our friendly sales team for assistance.