If purchasing a concrete sealer, contractors are absolutely spoilt for choice from basic acrylic sealers, penetrating sealers and high-performance epoxies and polyurethanes. Each sealer type has its own properties and purpose however all the above sealers can be categorised into either film-forming or penetrative. Penetrating sealers are an excellent way to protect concrete and offer many differences to film-forming sealers, particularly on large projects.

How they work

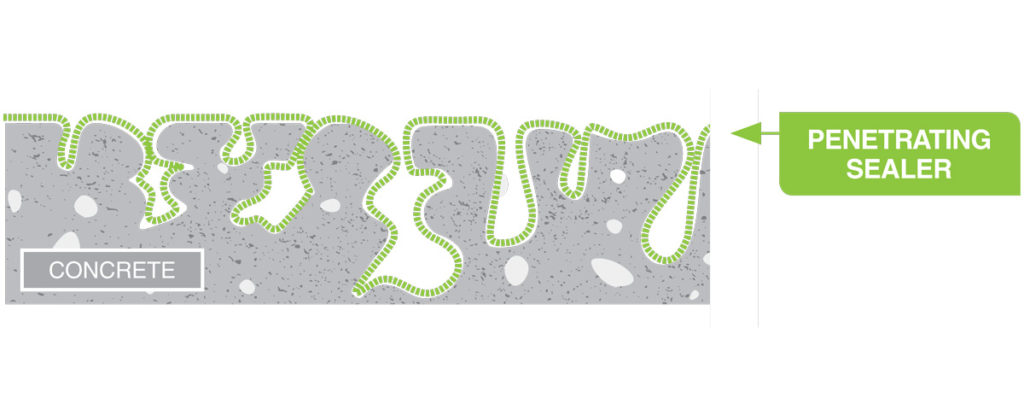

Penetrating sealers, as the name implies, work by infiltrating into the pores of the concrete to form a robust chemical barrier beneath the actual surface to prevent the penetration of water, moisture and grime. They do not usually change the appearance of the surface much, if at all, and most of theses sealers are permeable, thereby allowing evaporation of any damp that exists under the slab.

Once applied, penetrating sealers chemically react within the surface pores of the substrate to create a hydrophobic barrier which blocks the penetration by water and other substances. Because the surface is not being coated, penetrating sealers are the optimal choice for projects where it is imperative not to change the structure of the surface into one that becomes slippery, particularly when it is subject to moisture or rain.

As mentioned, penetrating sealers are an excellent choice on large outdoor projects as they will provide exceptional long-term protection against severe weather elements in addition to staining from a large array of spills. One of the best features of using a penetrating sealer is they generally won’t change the appearance of decorative or plain concrete and provide for a totally natural look. This is due to the fact that penetrating sealers are technically, not coatings.

Many different penetrating sealers exist to suit a vast range of residential and commercial applications from garage floors, driveways, pathways, pool surrounds, large retail spaces, industrial areas, alfresco areas and outdoor dining precincts. Product selection is usually done by what is needed in terms of protection from moisture and staining requirements and/or VOC (Volatile Organic Compounds) constraints of the project.

Application and maintenance process

The application of penetrating sealers is quite different to that of film-forming sealers and most require what is called a wet on wet application method. The reason for this is that concrete possesses different levels of porosity and to ensure maximum protection the sealer should be applied to the point of saturation to guarantee that the barrier is complete. Penetrating sealers should be applied by spraying or brooming, not rolling as rolling can lead to the product drying out too quickly which in turn prevents a wet on wet application. It is paramount that when applying more product that the product underneath is still damp, if not, then there is a strong likelihood of the new layer of product becoming cloudy.

Once concrete has been sealed with a penetrating sealer maintenance is very easy and usually only requires blowing, sweeping, mopping or pressure washing (irregularly) to have the surface looking pristine at all times. Of course, any spills such as oil, and other aggressive substances, wine and foodstuffs should be cleaned up as soon as possible.

The benefits

Overall, penetrating sealers offer many benefits and advantages for protecting concrete and natural stone. These include:

- An economical method for protecting both small and large areas of plain

- Available in many different formulations such as water and solvent-based varieties in addition to surface enhancing and extra stain-blocking properties types

- Can be used internally and externally on any concrete finish

- Suitable for plain and decorative concrete and natural stone such as Sandstone, Travertine, Blue Stone, Marble and Granite

- Available in low VOC Greenstar compliant versions

- Long-lasting and durable; lasting up to 5-6 years on high traffic pedestrian areas.