Galaxy Metallic Flooring system is ideal for any project where low upkeep, hardwearing and a WOW factor are essential benchmarks. Often used in commercial and showroom spaces, restaurants, cafes, salons and retail environments, hotel lobbies and entertainment rooms; it is a practical, low life cycle cost with bespoke aesthetics.

Application Guidelines

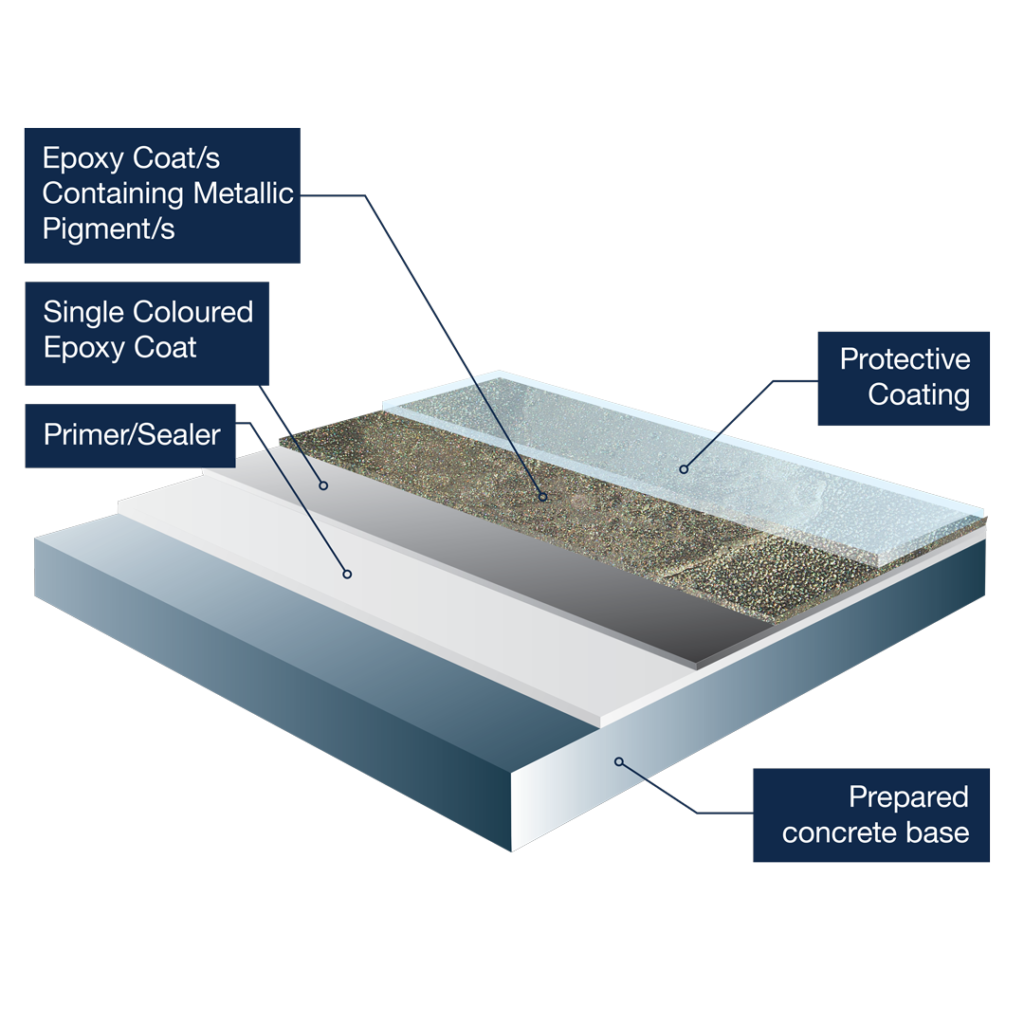

The process of creating a metallic epoxy floor is relatively straightforward and contains four steps. Preparation of the concrete surface will ensure a strong bond between the coatings and surface.

- Application of a Primer/Sealer

- Singular coloured Epoxy coat as the base

- Singular or several coats of Epoxy containing metallic pigment – During this process the applicator uses various techniques and tools to create a unique finish.

- Sealing with a protective coating

Step 1 – Application of a Primer/Sealer

CCS Ultra Epoxy Primer/Sealer WB

A high performance, two-part, clear, water-based coating system designed for sealing, priming, and protecting concrete from dust.

Step 2 – Singular coloured Epoxy coat

A two-part, solvent-free epoxy coating system designed for internal concrete floors that can be built up to an unlimited thickness and provides excellent water, chemical and oil resistance.

A high solid, two-component crystal clear, high gloss and high-performance trade strength floor coating system that can be used in any residential, industrial, and commercial setting.

A stir in universal colour concentrate for addition to a wide range of solvent-based, solvent-free and water-based sealing and priming products.

Step 3 – Singular or several coats of Epoxy containing metallic pigment

A high solid, two-component crystal clear, high gloss and high-performance trade strength floor coating system that can be used in any residential, industrial, and commercial setting.

Our Metallic Pigments are special effect pigments designed to mimic the natural look of stone and rock through pearlescent and iridescent light scattering effects. There are 10 colours that come in highly concentrated, ready to use packs which require no mixing, and are low VOC.

Step 4 – Sealing with a protective coating

A very durable, high gloss, two-part solvent-based polyurethane coating that provides excellent wear, chemical and stain resistance.

Decrathane is a low VOC, water-based, two-part coating that will protect the floor from solvents, chemicals, oils and acids while subtly enhancing the surface colour.

An extremely tough, high gloss and low odour coating that has been designed for commercial and industrial floors. This coating allows for use of the area in the same day as application with it being tack free within 45 minutes of application and capable of withstanding light pedestrian use within hours.

Top Tips to Achieving a Metallic Epoxy Floor

- It is virtually impossible to explain what the appearance of an epoxy metallic floor will be as each floor is unique. Take time to explain this to your client.

- If this is the first time applying a metallic floor, it is worth doing some experimentation first and providing your client with examples to ensure both parties are aware of the outcome.

- Always follow the manufacturer’s process to ensure a quality long-lasting floor.

Contact us today to receive a copy of our Galaxy Metallic Epoxy Floor brochure.